Anisotropic Crystalline Etch Simulation Software

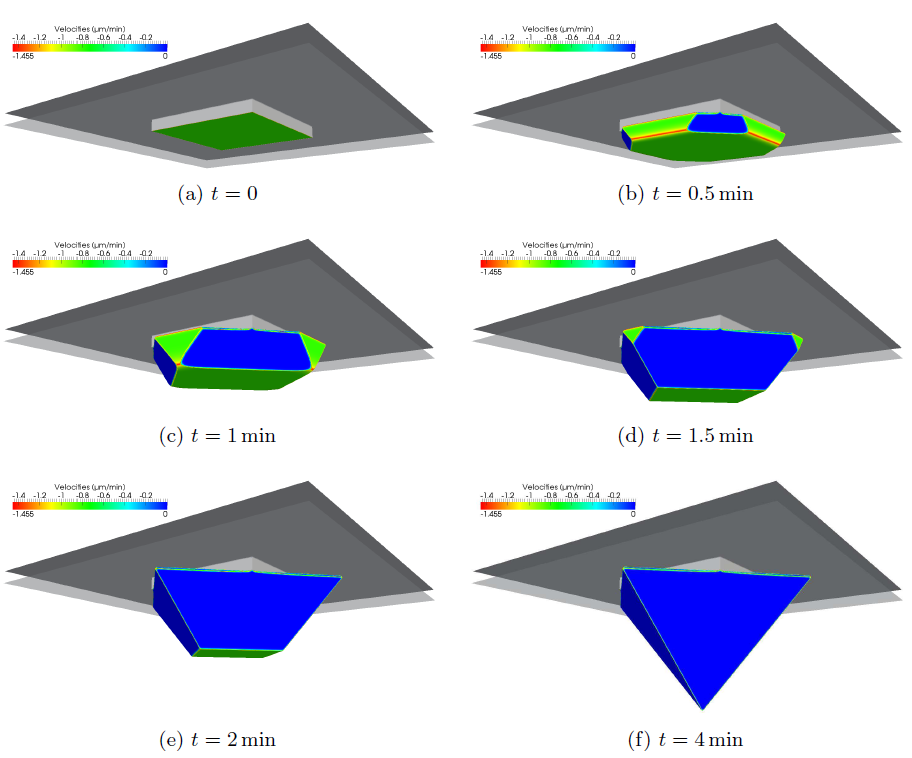

1. IntroductionAnisotropic crystal etching is the common technique used in Micro Electromechanical systems (MEMS) manufacturing. It uses the property of some single crystal materials, like silicon, of having different etching rates in different crystal directions when the material is etched in special chemicals, such as potassium hydroxide (KOH). Predicting the resulting shape of the structure under such conditions requires full three-dimensional simulation of the evolution of the etched surface.Silvaco's 3D process simulator VICTORY Process is perfectly suitable for such task. The numerical engine of VICTORY Process is able to accurately model physical etching with complicated distributions of etch rates over the surface even for initial structures with complex three-dimensional topographies.

Simulation Standard

- Anisotropic Crystalline Etching Simulation (ACES) software. Mechanical Engineering. Research output: Non-textual form › Software. Original language.

- Asaumi K, Iriye Y and Sato K 1997 Anisotropic etching process simulation system MICROCAD analyzing complete 3D etching profiles of single crystal silicon Proc. On Micro Electro Mechanical Systems (Nagoya) pp 412–7.

Anisotropic Crystalline Etch Simulation Software

1. IntroductionAnisotropic crystal etching is the common technique used in Micro Electromechanical systems (MEMS) manufacturing. It uses the property of some single crystal materials, like silicon, of having different etching rates in different crystal directions when the material is etched in special chemicals, such as potassium hydroxide (KOH). Predicting the resulting shape of the structure under such conditions requires full three-dimensional simulation of the evolution of the etched surface.Silvaco's 3D process simulator VICTORY Process is perfectly suitable for such task. The numerical engine of VICTORY Process is able to accurately model physical etching with complicated distributions of etch rates over the surface even for initial structures with complex three-dimensional topographies.Simulation Standard

- Anisotropic Crystalline Etching Simulation (ACES) software. Mechanical Engineering. Research output: Non-textual form › Software. Original language.

- Asaumi K, Iriye Y and Sato K 1997 Anisotropic etching process simulation system MICROCAD analyzing complete 3D etching profiles of single crystal silicon Proc. On Micro Electro Mechanical Systems (Nagoya) pp 412–7.

Anisotropic Crystalline Etch Simulation Model

A webinar on Anisotropic Etch Simulator for MEMS using Intellietch - A powerful simulation tool for etching. Presented by Joe Johnson, Intellisense Corporati.